Bearings – Roller bearings and sliding bearings

The history of bearing is already more than 2000 years old, for example, in old Egypt, the heaviest boulders, for the construction of the pyramids or other cultic sites, were stored on simple wooden tracks to transport them over large distances. It was already ascertained that the required power was significantly lower when logs were used instead of the skids.

In the 16th century, it was Leonardo da Vinci, who dealt scientifically with the topic of abrasion and developed determining insights into the function of rolling and sliding bearings – for example, the cage for the roller elements. The invention of the steam engine, at the beginning of the industrial revolution, brought the real breakthrough for the machine element bearings.

Use and construction of roller bearings

Roller bearings are one of the most commonly used machine components today. Wherever loads are supported or guided, bearings are in use. So the essential functions are the transmission of movement and the transmission of forces. One distinguishes between sliding and rolling bearings. In sliding bearings, the power transmission and the rotational movement take place between so-called sliding surfaces.

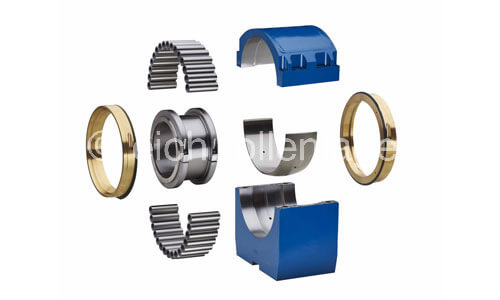

Roller bearings are composed of an inner ring, an outer ring and the roller elements arranged therebetween. These roller elements provide a low-friction movement and power transmission. Roller bearings are clearly superior to sliding bearings, especially in slow-turning applications.

Ball bearings and roller bearings

Roller bearings can transmit forces in the radial and / or axial direction. Also a distinction is made between ball bearings and roller bearings. In ball bearings, the rolling element is a ball and in roller bearings a roller, a cylindrical roller, a barrel roller, a needle roller, a tapered roller or a flexible roller.

Standard bearings or special bearings (Different types of roller bearings)

Basically, a distinction is made between roller bearings with point contact (ball bearings) and roller bearings with line contact (roller bearings). Rolling bearings can also be differentiated according to the mode of loading, namely radial roller bearings and axial roller bearings. Some roller bearings are combined loadable.

Nowadays rolling bearings are considered mature machine elements. DIN 611:2010-05 provides an overview of most types, individual parts, designations and the associated national and international standards. Further standards define e.g. the dimensions (DIN 616: 2000-06), the materials (DIN EN ISO 683-17: 2015-02) or the calculation (DIN 26281: 2010-11, DIN ISO 76: 2009-01). This regulatory framework then also describes and defines the performance parameters of the standard roller bearings, such as the operating conditions or the durability.

Manufacture of special roller bearings

However, there are also limiting conditions that preclude the use of standard bearings, such as extreme operating conditions (high temperatures, high impact loads, etc.) or even geometric restrictions. In these cases, special roller bearings are used.

This is the range in which Eich Rollenlager GmbH has specialized and has now gathered over 75 years of experience. Eich has built up competencies and has established itself as a reliable partner for the industry. The slogan of the company Eich is: We develop bearings / solutions that become standards instead of the other way round.

3D measurement of rolling bearings

The bearings produced have to be measured again and again during production so that the dimensions are exactly right. The following video shows a quality control of a rolling bearing in the house of Eich Rollenlager GmbH. This is done using the latest measuring equipment and qualified employees.

Roller bearing types

ABC-Roller-Bearing

The ABC roller bearing stands for the so-called Anti Blocking Cage, which represents a special form of Spring bushing bearings compared to the usual solid roller cages. The ABC stock has a snap cage instead.

Spring bushing roller bearing

The spring bushing roller bearings and spring roller bearings form the original brand core of Eich and have been manufactured since the founding days of Eich. Initially, some of these types of bearings had been used in various mining applications.

Cylindrical roller bearings

Split roller bearings

Split roller bearings are a special design that is specially adapted to specific applications, such as cranked drive shafts (driven strand guide rollers, support bearings for long / heavy drive spindles), very long drive shafts (shafts, drive shafts in cooling beds) or hard to reach bearings (drive shaft of a heavy fan).

SACRB roller bearings

More roller bearing types