Production quality

Quality that binds, cares for motion.

Starting with the nature of the problem and the description of the application, Eich develops and produces anti-friction roller bearings with a very high-degree of customisation. This continues through into production where batch sizes starting at just one piece demand a high degree of flexibility.

Depending on the customer requirements and/or requirements of the application, the bearings can be manufactured from high-tensile, high-temperature or rust-free roller bearing steels. Normal roller bearing steels are used as standard material.

The range of roller bearings manufactured begins at an inside diameter of 30 mm and ends at 1000 mm. There is an enormous depth in the production process: From the product development stage right up to the final acceptance, everything is carried out under a single roof. CAD, work piece preparation on modern CNC machines, soft/hard machining and heat treatment are seamlessly integrated into one another at Eich and are subject to constant quality checks.

That is the basis for short delivery times, optimum production quality and value added pricing.

Know-how

Our commitment to roller bearings

is what keeps us moving.

In close cooperation with our customers, we develop and produce roller bearings with a high degree of individuality, adapted precisely to the demands of the intended application.

Eich sees itself as a technology development partner for the industry who already provides its technical know-how at the planning and development phase of plants and machines. And Eich remains a competent partner also for later optimisation. The close cooperation with our customers forms the basis for the development of roller bearings to meet the individual requirements.

As a member of the German Research Association for Drive Technology (FVA) in the Antifriction Bearing working group, we remain in close contact with the innovations in the branch and are involved in the support for research projects and work together with the research institutes of leading universities.

Philosophy

Individual requirements demand tailor-made solutions of the highest quality.

Translating simple principles of bearing technology into high-quality and tailor-made solutions for our customers – that is our philosophy.

The principle of simplicity is reflected in all areas of the company and also contributes to transparency.

This principle is adopted in production by highly qualified employees. Our location in Germany enables us to continually ensure the same. Focusing on customer needs, our production is extremely flexible and constantly works towards the simplification of the production process. With their years of experience, our employees know what is called for and often contribute to product-specific improvements with their ideas.

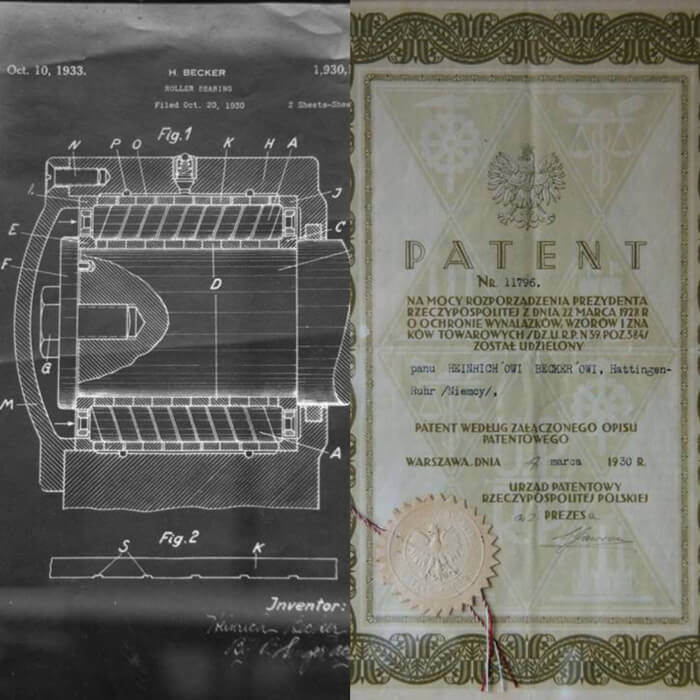

History

Setting the ball rolling worldwide.

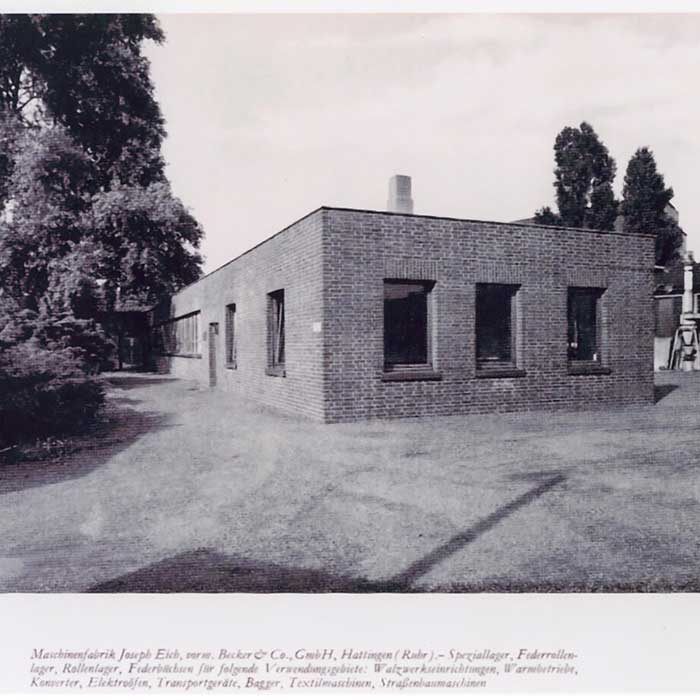

The Maschinenfabrik Joseph Eich KG was founded in Hattingen in 1939 as a metalworking company during the boom years in the mining and steel industries. At that time, 15 employees were engaged in the pioneering task of developing and producing a type of bearing that was completely new to Germany: The spring roller bearing. Completely new here was the development of the inner and outer rings for this bearing type: Internal and external spring bushings.

The company quickly established itself as a highly specialised supplier and focused its attention on the growing steel and heavy industries in the 40’s and the 50’s. Today, Eich is renowned worldwide as a supplier and producer of spring roller bearings, anti-friction bearings and as a competent partner for special solutions.

Success

Success and innovation.

The crises that hit the roller bearing industry in the 90’s led to major changes also at Eich. We have been able to adapt the changing demands by modifying our production processes, expanding our product portfolio and improving our organization. The positive development over the last decade has endorsed these management decisions.

This success is built on three pillars: The close co-operation over decades with the leading OEMs of continuous casting plants.

The constant exchange of knowledge and experience with reputed plant operators, both in Germany and abroad, that has led to further improvements and new developments in the plants.

The employees of the company who see the customers’ demands in a wider setting and provide intensive support to the supply of a product through comprehensive service. The following are examples of the innovativeness of our employees: In two manufacturing areas – spring ring production and external grinding – we have built two machine tools for our own works that have lead to increased flexibility, work safety and improvements in the product.

Certified

Eich Rollenlager GmbH acts as a certified company. Gradually, our rolling bearings have been optimized, improved and proven. Click here for the certificate.